PET Granulating mutsara

Infrared Crystallization Dryer ye rPET Extrusion granulating line

Infrared Pre-Drying yerPET Bottle Flakes: Kuwedzera Kubuda uye Kuvandudza Hunhu paPET Extruders.

Kuomesa ndiyo imwechete yakakosha shanduko mukugadzirisa.

>> Kuvandudza magadzirirwo uye emuviri zvivakwa zvekudzokororwa, chikafu-giredhi PET kuburikidza tekinoroji inofambiswa nemwenje infrared ine chikamu chakakosha kuita mumukati viscosity (IV) pfuma.

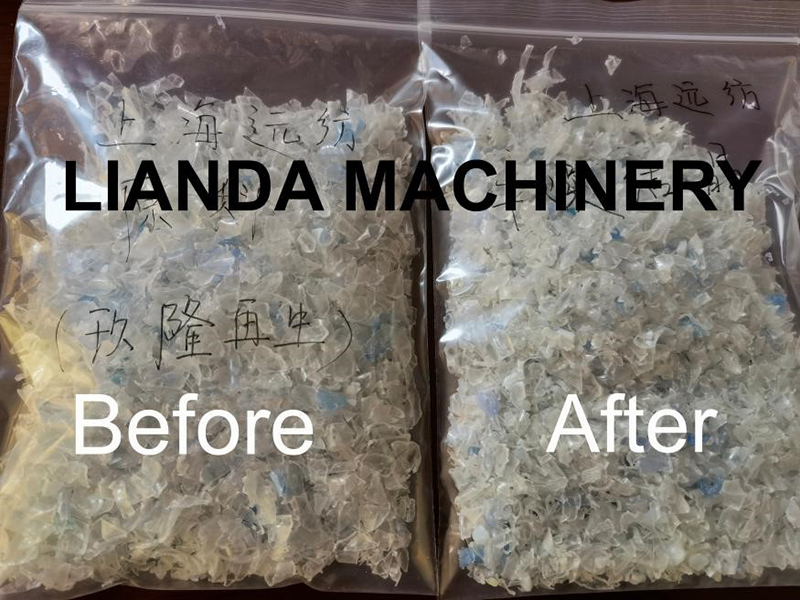

>> Pre-crystallization & kuomeswa kwemaflakes kusati kwaitwa extrusion kunobatsira kuderedza kurasikirwa kweIV kubva kuPET, chinhu chakakosha chekushandisa zvakare resin.

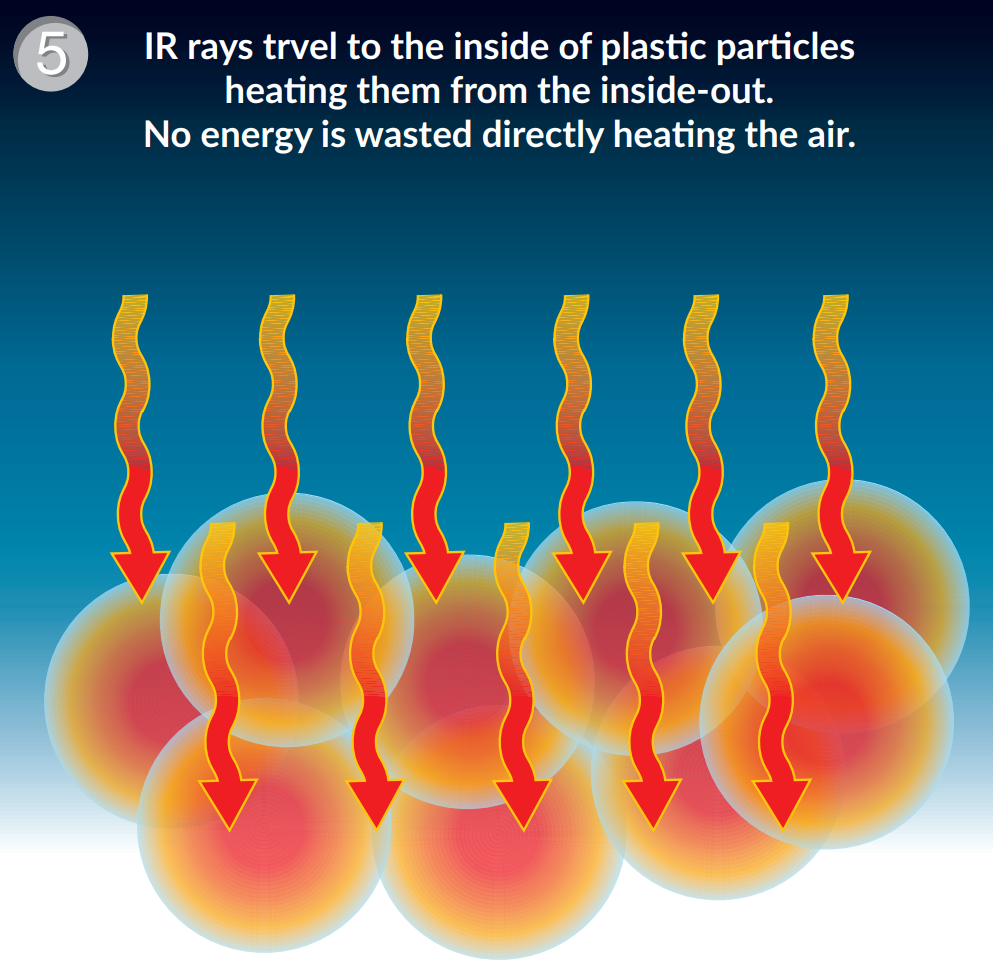

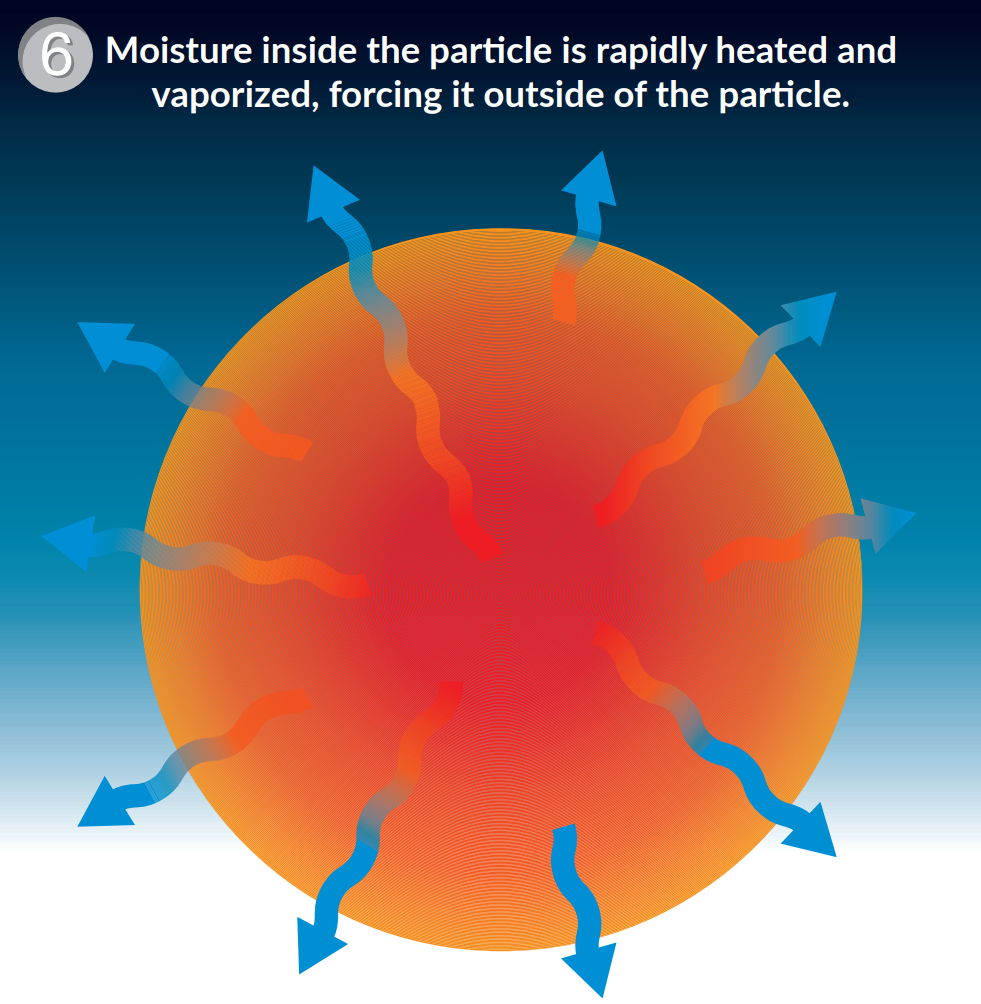

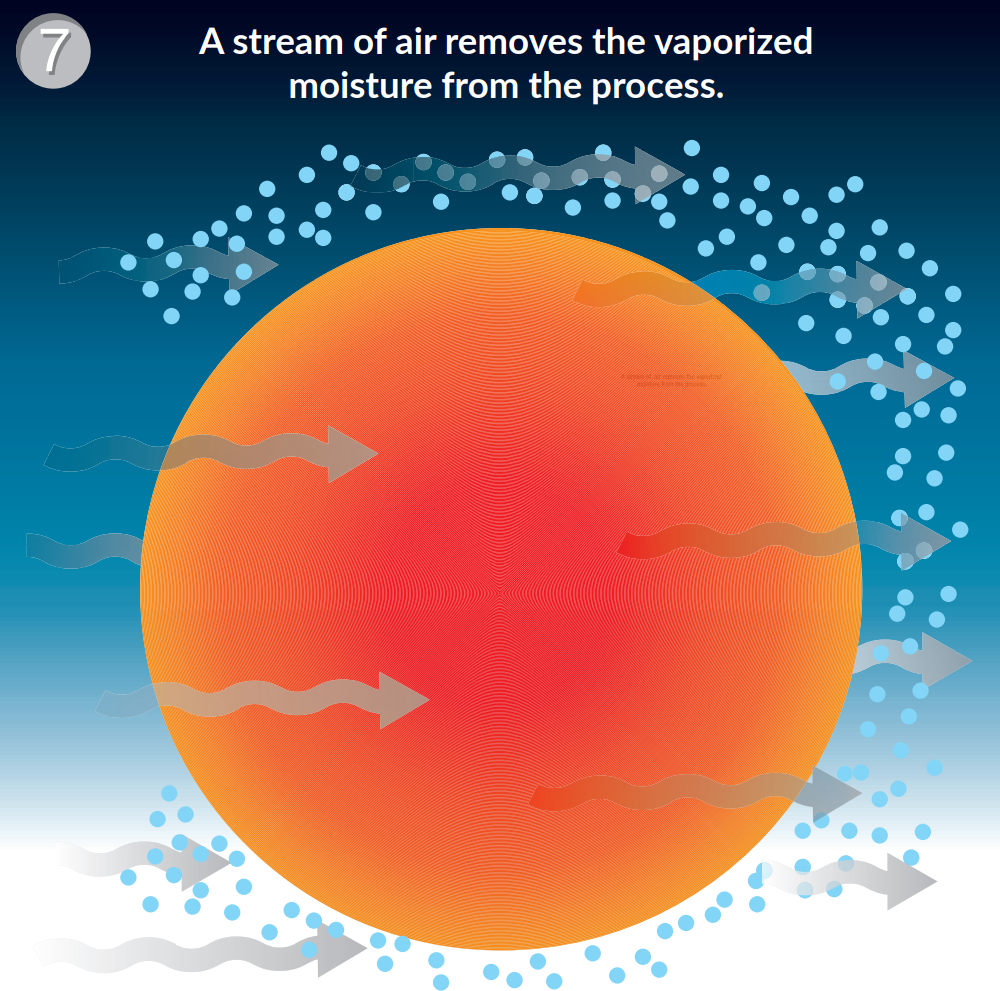

>> Reprocessing the flakes in the extruder inoderedza IV nekuda kwe hydrolysis i kuvapo kwemvura, uye ndosaka pre-kuomeswa kune homogeneous yekuomesa pamwero neIRD System yedu inogona kudzikamisa kuderedzwa uku. Mukuwedzera,iyo PET yakanyunguduka mitsetse haishanduke yero nekuti nguva yekuomesa yakaderedzwa(Kuomesa nguva kunongoda 15-20mins, unyoro hwekupedzisira hunogona kuva ≤ 30ppm, kushandiswa kwesimba pasi pe80W / KG / H)

>>Kuveura muextruder kunoderedzwawo nekuti iyo preheated zvinhu inopinda muextruder painopisa tembiricha”

>> Kuvandudza kubuda kwePET Extruder

Kuwedzera kwehuwandu hwehuwandu negumi kusvika makumi maviri muzana kunogona kuwanikwa muIRD, kunonatsiridza mashandiro ezvekudya pane extruder inlet zvakanyanya - nepo extruder yekumhanyisa inoramba isina kuchinjika, pane yakagadziridzwa kuzadza mashandiro pane screw.

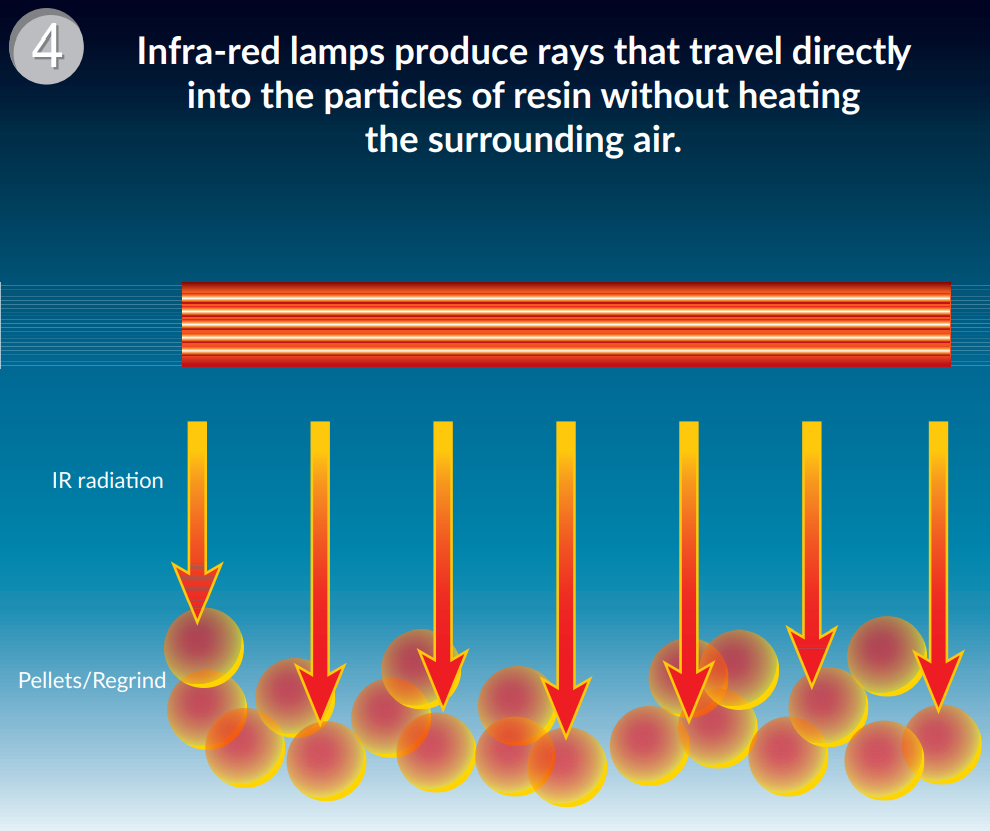

Kushanda Nheyo

Advantage We Make

※Kuderedza iyo hydrolytic degradation yeiyo viscosity.

※ Dzivirira kuwedzera AA mazinga emidziyo ine chikafu chekubata

※ Kuwedzera kugona kwemutsara wekugadzira kusvika ku50%

※ Kuvandudza uye ita kuti chigadzirwa chigadzikane-- Yakaenzana uye inodzokororwa yekuisa mwando yemukati mechinhu

→ Deredza mutengo wekugadzira wePET pellets: Kusvika ku60% kushoma kushandiswa kwesimba pane kwakajairwa kuomesa system

→ Kukurumidza kutanga uye nekukasira kudzima --- Hapana chinodiwa pre-kudziya

→ Kuomesa & crystallization ichagadziriswa mune imwe nhanho

→ Mutsetse wemuchina wakashongedzerwa neSiemens PLC system ine imwe kiyi yekurangarira basa

→ Inovhara nzvimbo yediki, yakapusa chimiro uye iri nyore kushandisa uye kugadzirisa

→ Tembiricha yakazvimirira uye yekuomesa nguva yakatarwa

→ Hapana kupatsanurwa kwezvigadzirwa zvine huwandu hwakawanda hwakasiyana

→ Kuchena nyore uye shandura zvinhu

Muchina Unomhanya mufekitari yeVatengi

FAQ

Mubvunzo: Ndeupi hunyoro hwekupedzisira hwaunogona kuwana? Iwe une chero chinogumira pakunyorova kwekutanga kweiyo mbishi zvinhu?

A: Hunyoro hwekupedzisira tinogona kuwana ≤30ppm (Tora PET semuenzaniso). Yekutanga mwando inogona kuva 6000-15000ppm.

Mubvunzo: Isu tinoshandisa Double parallel screw extruding ne vacuum degassing system yePET Extrusion granulating line, tichange tichida kushandisa pre-dryer?

A: Isu tinokurudzira kushandisa Pre-dryer isati yasvika. Kazhinji sisitimu yakadaro ine chinodikanwa chakasimba pane yekutanga hunyoro hwePET zvinhu. Sezvatinoziva PET imhando yezvinhu zvinogona kutora hunyoro kubva mumhepo izvo zvinokonzeresa mutsara weextrusion kushanda zvakaipa. Saka isu tinokurudzira kushandisa pre-dryer isati yako extrusion system:

>> Kudzikamisa iyo hydrolytic kuderedzwa kweiyo viscosity

>>Dzivirira kuwedzera AA mazinga emidziyo ine chikafu chekubata

>> Kuwedzera kugona kwemutsara wekugadzira kusvika ku50%

>> Kuvandudza uye ita kuti chigadzirwa chigadzikane-- Yakaenzana uye inodzokororwa yekuisa mwando yemukati mechinhu chacho

Mubvunzo: Ndeipi nguva yekuendesa yeIRD yako?

A: Mazuva makumi mana ekushanda kubva patakawana dhipoziti yako muakaundi yekambani yedu.

Mubvunzo: Zvakadini nekuiswa kweIRD yako?

Injiniya ane ruzivo anogona kubatsira kuisa iyo IRD system yako mufekitori yako. Kana kuti isu tinogona kupa gidhi sevhisi pamutsara. Muchina wese unotora plug yekubhururuka, nyore kubatanidza.

Mubvunzo: Ndeipi IRD inogona kushandisirwa?

A: Inogona kuva pre-dryer ye

- PET/PLA/TPE Sheet extrusion muchina mutsetse

- PET Bale tambo yekugadzira muchina mutsara

- PET masterbatch crystallization uye kuomesa

- PETG Sheet extrusion line

- PET monofilament muchina, PET monofilament extrusion line, PET monofilament yemutsvairo

- PLA / PET Mafirimu ekugadzira muchina

- PBT, ABS/PC, HDPE, LCP, PC, PP, PVB, WPC, TPE, TPU, PET (Bottleflakes, granules, flakes), PET masterbatch, CO-PET, PBT, PEEK, PLA,PBAT, PPS nezvimwe.

- Thermal maitiro eiyokubviswa kwekuzorora oligomeren uye zvikamu zvinoputika.