PLA PET thermoforming Sheet extrusion line

Infrared crystal dryer+ PET Sheet Extrusion line

Advantage yatinoita

>>LIANDA inogadzira iyoSingle screw extrusion line ine Infrared crystal dryeryePET sheet, 20mins pre-drying uye crystallization, hunyoro hwekupedzisira hunogona kuva ≤50ppm (Muchina mutsetse Shanda zvakadzikama, yekupedzisira pepa remhando yakagadzikana)

Iyo extrusion line ine zvimiro zvepasi simba rekushandisa, nyore kugadzira maitiro uye nyore kugadzirisa.

Iyo yakakamurwa screw chimiro inogona kuderedza viscosity kurasikirwa kwePET resin, iyo symmetrical uye yakatetepa-wall calender roll inovandudza kutonhora maitiro, kugona uye pepa mhando.

Mult-components dosing feeder inodzora huwandu hwezvinhu zvitsva, kudzokorodza zvinhu uye master batch chaizvo,.

Iyo pepa yakashandiswa zvakanyanya kune thermoforming yekurongedza indasitiri.

>>Infrared crystal dryer -----Dry &Crystallize R-PET flakes/chips mu20mins pa30ppm nekuchengetedza 45-50% mutengo wesimba.

※Kuderedza iyo hydrolytic degradation yeiyo viscosity.

※ Dzivirira kuwedzera AA mazinga emidziyo ine chikafu chekubata

※ Kuwedzera kugona kwemutsara wekugadzira kusvika ku50%

※ Kuvandudza uye ita kuti chigadzirwa chigadzikane-- Yakaenzana uye inodzokororwa yekuisa mwando yemukati mechinhu

Deredza mutengo wekugadzira wePET sheet: Kusvika 60% kushoma kwesimba rekushandisa pane yakajairwa kuomesa system

Kukurumidza kutanga uye nekukasira kudzima --- Hapana chinodiwa pre-kudziisa

Kuomesa & crystallization ichagadziriswa mune imwe nhanho

Kuti uvandudze simba rekusimba rePET sheet, Wedzera kukosha kwakawedzerwa--- Kunyorova kwekupedzisira kunogona kuve ≤30ppm ne20minsDry & Crystallization

- Mutsetse wemuchina wakashongedzerwa neSiemens PLC system ine imwe kiyi yekurangarira basa

- Inovhara nzvimbo yediki, yakapusa chimiro uye iri nyore kushanda nekugadzirisa

- Kuzvimiririra tembiricha uye kuomesa nguva yakatarwa

- Hapana kupatsanurwa kwezvinhu zvine huwandu hwakasiyana densities

- Easy yakachena uye shandura zvinhu

>> PET Extrusion muchina mutsetse

| Model | Multi layer | Single layer | Zvikuru-zvinobudirira |

| Extruder tsanangudzo | LD75&36/40-1000 | LD75/40-1000 | LD95&62/44-1500 |

| Ukobvu hwechigadzirwa | 0.15-1.5mm | 0.15-1.5mm | 0.15-1.5mm |

| Main mota simba | 110kw/45kw | 110kw | 250kw/55kw |

| Max extrusion kugona | 500kg/h | 450kg/h | 800-1000kg/h |

Machine list

| Machine Composition | ||

| NO | Machine | Quantity |

| 1 | PET Infrared crystal dryer | 1 set |

| 2 | Vacuum screw feeder | 1 set |

| 3 | Kaviri screw extruder | 1 set |

| 4 | Vacuum negative pressure system | 1 set |

| 5 | Kaviri chiteshi sefa | 1 set |

| 6 | Sungunusa metering pombi | 1 set |

| 7 | PET yakakosha mold inofa | 1 set |

| 8 | Three-roll calendering ichiita chikamu | 1 set |

| 9 | Silicone mafuta ekuputira uye Ovheni mudziyo | 1 set |

| 10 | Edge zvinhu zvekucheka mudziyo | 1 set |

| 11 | Edge zvinhu kudzoreredza mudziyo | 1 set |

| 12 | Double station winding system | 1 set |

| 13 | SIEMENS munhu-muchina interface control system | 1 set |

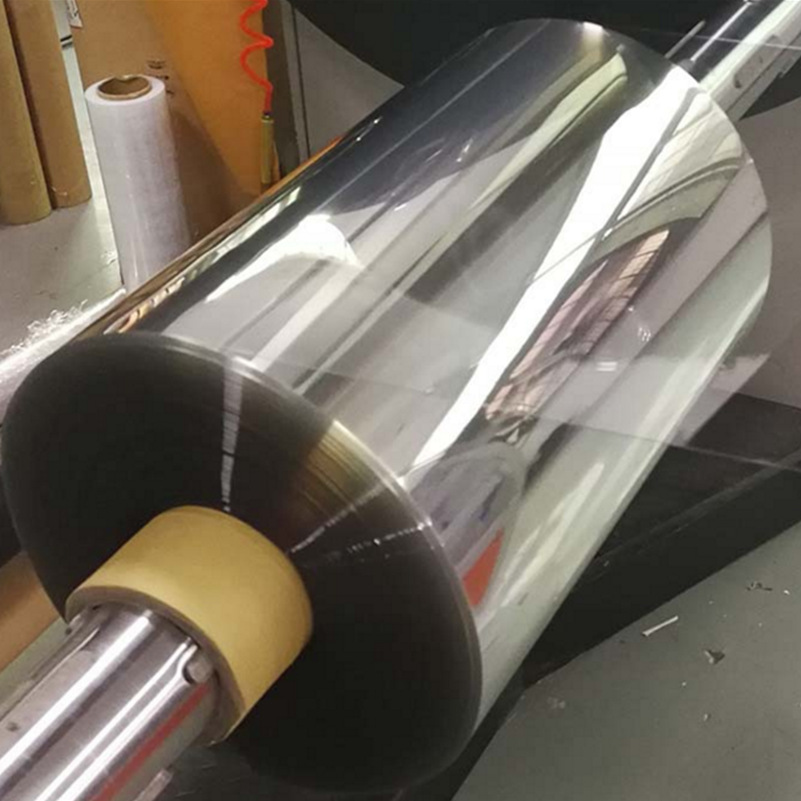

Machine Photos

FAQ

Mubvunzo: Ndeupi hunyoro hwekupedzisira hwaunogona kuwana? Iwe une chero chinogumira pakunyorova kwekutanga kweiyo mbishi zvinhu?

A: Hunyoro hwekupedzisira tinogona kuwana ≤30ppm (Tora PET semuenzaniso). Yekutanga mwando inogona kuva 6000-15000ppm.

Mubvunzo: Isu tinoshandisa Double parallel screw extruding ne vacuum degassing system yePET Sheet extrusion, tichange tichida kushandisa pre-dryer?

A: Isu tinokurudzira kushandisa Pre-dryer isati yasvika. Kazhinji sisitimu yakadaro ine chinodikanwa chakasimba pane yekutanga hunyoro hwePET zvinhu. Sezvatinoziva PET imhando yezvinhu zvinogona kutora hunyoro kubva mumhepo izvo zvinokonzeresa mutsara weextrusion kushanda zvakaipa. Saka isu tinokurudzira kushandisa pre-dryer isati yako extrusion system:

>> Kudzikamisa iyo hydrolytic kuderedzwa kweiyo viscosity

>>Dzivirira kuwedzera AA mazinga emidziyo ine chikafu chekubata

>> Kuwedzera kugona kwemutsara wekugadzira kusvika ku50%

>> Kuvandudza uye ita kuti chigadzirwa chigadzikane-- Yakaenzana uye inodzokororwa yekuisa mwando yemukati mechinhu chacho

Mubvunzo: Tichashandisa zvinhu zvitsva asi isu hatina ruzivo rwekuomesa zvinhu zvakadaro. Unogona kutibatsira here?

A: Fekitari yedu ine Test Center. Munzvimbo yedu yeTest, tinogona kuita zviyedzo zvinoenderera kana zvisingaendereki kune zvemutengi sampuli zvinhu. Midziyo yedu inopihwa yakazara otomatiki uye kuyerwa tekinoroji.

Tinogona kuratidza --- Kutakura / Kurodha, Kuomesa & Crystallization, Kuburitsa.

Kuomesa uye crystallization yezvinhu kuti uone zvakasara mwando, nguva yekugara, simba rekuisa uye zvinhu zvenyama.

Isu tinogona zvakare kuratidza kuita nekuita subcontracting kune mabhechi madiki.

Zvinoenderana nezvako zvekushandisa uye zvekugadzira zvinodiwa, isu tinokwanisa mepu kuronga newe.

Injiniya ane ruzivo achaita bvunzo. Vashandi vako vanokokwa neushamwari kuti vatore chikamu mumakwara edu akabatana. Saka iwe une zvese mukana wekupa nesimba uye mukana wekuona chaizvo zvigadzirwa zvedu zviri kushanda.

Mubvunzo: Ndeipi nguva yekuendesa yeIRD yako?

A: Mazuva makumi mana ekushanda kubva patakawana dhipoziti yako muakaundi yekambani yedu.

Mubvunzo: Zvakadini nekuiswa kweIRD yako?

Injiniya ane ruzivo anogona kubatsira kuisa iyo IRD system yako mufekitori yako. Kana kuti isu tinogona kupa gidhi sevhisi pamutsara. Muchina wese unotora plug yekubhururuka, nyore kubatanidza.

Mubvunzo: Ndeipi IRD inogona kushandisirwa?

A: Inogona kuva pre-dryer ye

PET/PLA/TPE Sheet extrusion muchina mutsetse

PET Bale tambo yekugadzira muchina mutsara

PET masterbatch crystallization uye kuomesa

PETG Sheet extrusion line

PET monofilament muchina, PET monofilament extrusion line, PET monofilament yemutsvairo

PLA / PET Mafirimu ekugadzira muchina

PBT, ABS/PC, HDPE, LCP, PC, PP, PVB, WPC, TPE, TPU, PET (Bottleflakes, granules, flakes), PET masterbatch, CO-PET, PBT, PEEK, PLA,PBAT, PPS nezvimwe.

Thermal maitiro eiyokubviswa kwekuzorora oligomeren uye zvikamu zvinoputika.